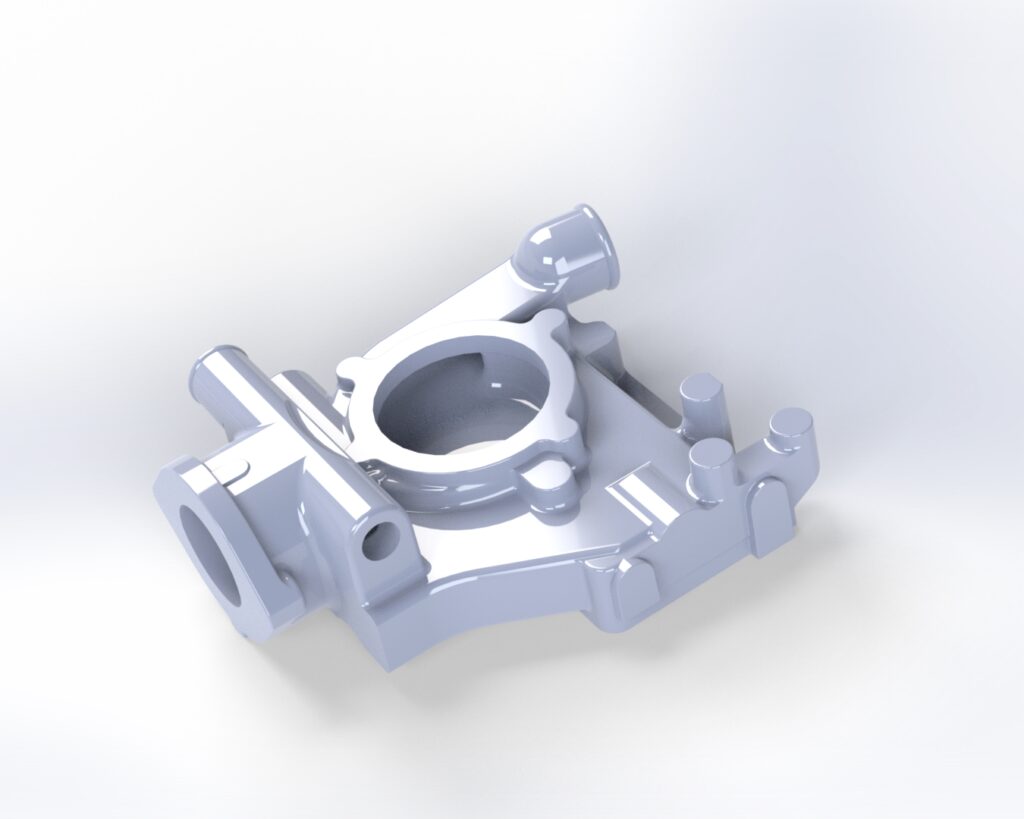

Case Study: Simulation-Driven Rescue of a Cast-Iron Water Pump Body

From chronic cold-shuts to <1% defects at scale—how a classic CI pump body hit 82% yield and shipped >10,000 units on time.

- Yield ~82%

- Defects <1% over 10,000+ units

- Order recovered on schedule

The Problem

No 3D model—only legacy drawings and a troubled “current part”

Cold-shuts and misruns in green sand

Drafts/tapers wrong → dimensional drift, drying distortion

Behind on a 10k+ unit order; heavy scrap.

Our Approach

Rebuilt the 3D model (from drawings + measured part; fixed drafts/tapers).

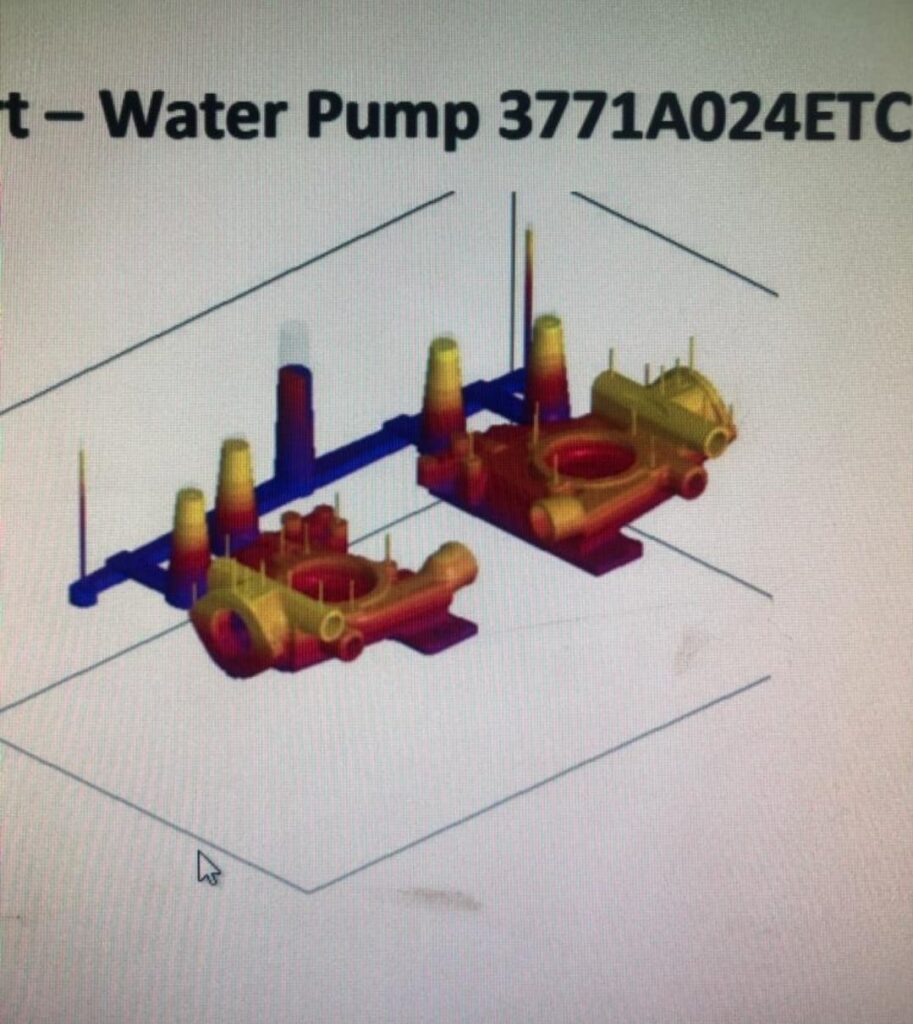

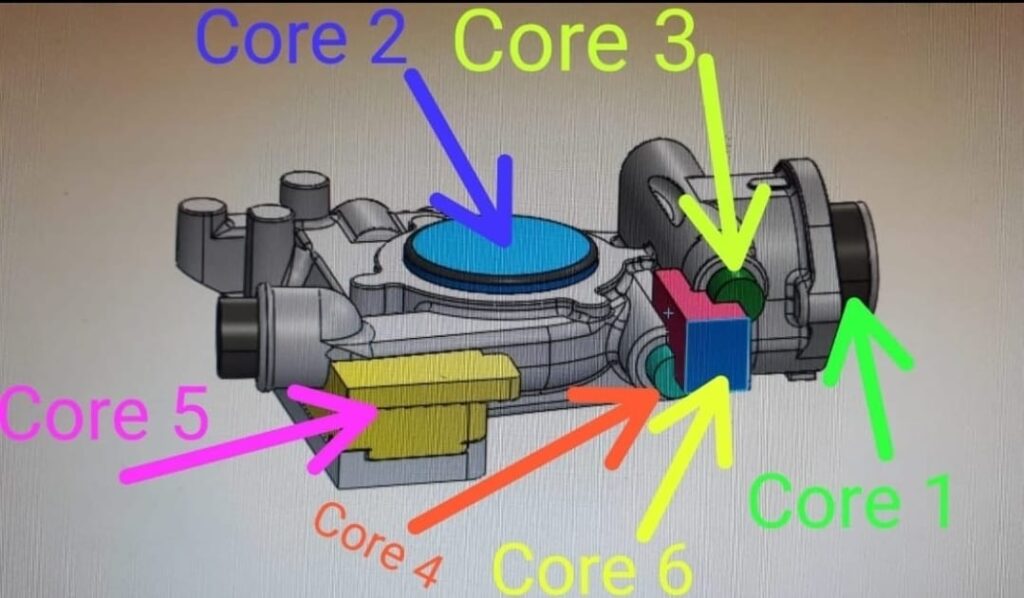

Ran casting simulations to eliminate cold-shut vectors.

Printed an ABS master for dimensional sign-off.

Finalized gating/feeding and core design; built pattern/coreboxes.

Shop-floor launch with alloy guidance, pour window, and molding notes.

Key design choices

- Balanced runners; smooth front-fill (reduce bifilm)

- Risers repositioned for directional solidification

- Cleaned internal transitions (less turbulence/oxide entrapment)

- Draft/taper corrections for consistent green-sand release

Results

Scrap: frequent cold-shuts

Yield: ~65–70% (est.)

Delivery: behind

Dimensions: variable

After

Defects: <1% (client-reported)

Yield: ~82%

Delivery: recovered

Dimensions: passed ABS + in-process checks

Implementation Notes

- Process: green sand, cast iron (per customer spec)

- Pour window & chemistry guidance provided

- Tooling: pattern + coreboxes (delivered)

- Launch support: first-pour assistance + molding notes

Struggling with cold-shuts or yield?

We design the gating, prove it in simulation, and stand beside your first pours.

Typical response within 1 business day.